Productivity Unleashed

Mobil Vactra - A smoother path to precision machining

Advanced lubrication solutions can help machine shops slide their way into the lead.

Machine shop owners are under pressure across-the-board. Lead times continue to reduce, the demand for machining accuracy has never been higher and regulatory requirements are adding complexity to to-day-day operations. Firms are feeling besieged from all directions, but maintaining an effective operation in the face of all these challenges is essential if business objectives are to be achieved. Part of the answer to safeguarding cutting accuracy and shop floor productivity is to ensure machinery is properly maintained and operating at peak efficiency, which requires the deployment of high performance lubricants. However, for machine shop operators, it’s not that simple.

Lubrication plays an integral role in reducing friction between rotating and moving components in a manufacturing plant. Indeed, in most applications, this is an oil’s main purpose, helping increase equipment availability, component quality and production uptime. Machine tools, however, demand a very different approach. To lubricate horizontal and vertical slideways, for example, simply reducing friction isn’t enough. Specifically-engineered lubricants are required to ensure smooth and controlled movement. Critically, the compatibility of this slideway oil with other lubricants in the machine tool can also have a significant effect on overall productivity. Selecting the right formulation can help operators achieve their business goals.

Frictional Control

Slideway lubricants are intended to reduce friction, prevent wear and provide long-term protection against corrosion and rust. Without optimum frictional control, a condition known as ‘stick-slip’ can occur. This abnormal movement between slider and slideway can quickly depreciate the surface finish and quality of components, impacting tool life, causing excessive wear and long-lasting critical equipment damage. Smooth and precise movement on the slideway requires special attention to a lubricant’s frictional properties.

Fortunately, premium-quality slideway lubricants such as Mobil Vactra™ are an effective remedy for the stick-slip phenomenon. Engineered specifically for sensitive machine tool slideways, Mobil Vactra has been meticulously researched, tested and updated. It features a unique blend of additives, which work in synergy to adhere to the surface and ensure smooth transitions from static to dynamic frictional control. These properties offer maintenance professionals enhanced precision machining and tool life.

Compatibility with Aqueous Coolants

Some slideway oils have not been formulated to separate readily from aqueous coolants. This often creates ‘tramp oil’ on the surface of the coolant sump in the machine tool, compromising its effectiveness by shortening its service life. Excess surface tramp oil promotes bacterial growth, resulting in foul odour, sticky deposits and potential health and safety concerns for operators. To ensure that machine tools run smoothly, therefore, it is important to choose the right combination of premium quality slideway oil and aqueous cutting fluid.

Mobil Vactra has been engineered to offer excellent separability between itself and a wide range of coolant types, including milky, micro-emulsion and fully-synthetic products. This enhanced compatibility supports long coolant life, avoids foul smells and enables optimal machining precision. By reducing the problems associated with cross-contamination, Mobil Vactra offers extended fluid life, easier waste management, reduced maintenance costs and an improved working environment.

Backed by Builder Endorsements

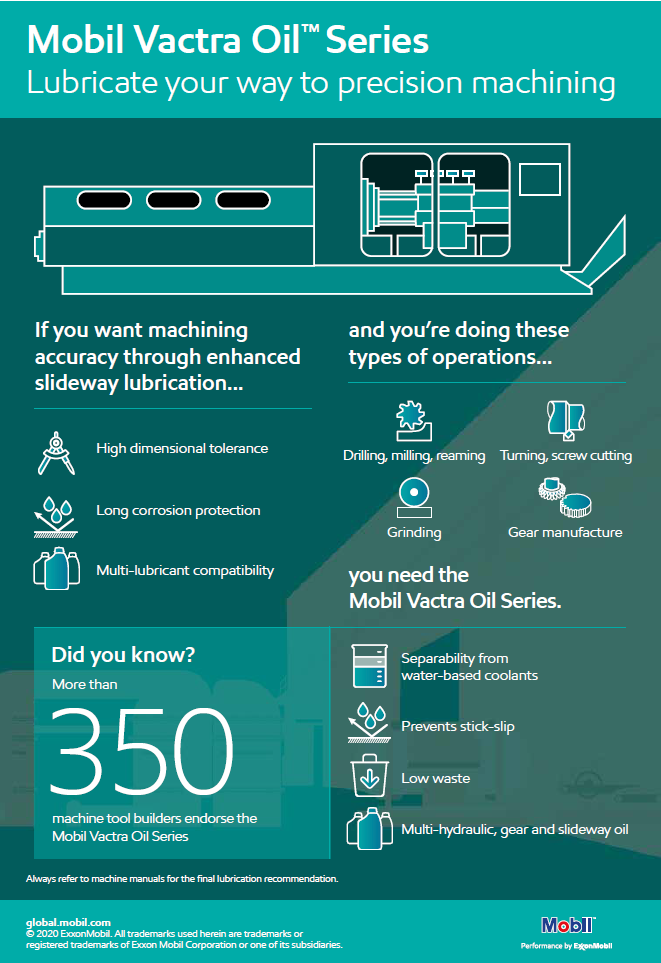

The technology behind Mobil Vactra is endorsed or approved by leading builders all over the world. Some even preferentially or exclusively endorse its use in their equipment *. The products in the series meet the DIN 51502 CGLP specification and, depending on the viscosity, the Fives Cincinnati approval. Always check your machine tool manual before final selection.

The Mobil Vactra Oil Numbered Series are premium-quality Slideway lubricants specifically designed to meet the requirements for accuracy, aqueous coolant separability, and equipment protection of precision machine tools.

The Mobil Vactra Oil Numbered Series is carefully formulated from high-quality base stocks and performance balanced with an advanced additive system that provides controlled frictional properties, compatibility with aqueous metal working fluids and corrosion protection of parts and equipment. The unique additive package provides exceptional frictional properties on a wide variety of way materials, including steel on steel and steel on polymer, reducing stick-slip and chatter. This allows smooth, uniform motion at design travel speeds enhancing machine productivity and accuracy helping to prolong tool life and enhance surface finish. The Mobil Vactra Oil Numbered Series has been optimized to provide separability from many aqueous coolants while minimizing the corrosive effects of high pH coolants on lubricated surfaces.

Features and Benefits

The Mobil Vactra Oil Numbered Series has been developed and specifically designed to provide an extra margin of machinery protection by satisfying the stringent demands of slide ways. The oils exhibit excellent lubricity and load-carrying performance contributing significantly to improving the production of quality parts. The Mobil Vactra Oil Numbered Series provides separability from many water and aqueous coolants reducing the potential negative effects of cross contamination which helps to enhance the service life and performance of both the lubricant and coolant.